Peter Grossi |

Peter’s principal interest lies in electronic design and programming, but has diversified into mechanical design and 3- A keen Linux user, his design weapons of choice are KiCAD (electronics), FreeCAD (3- He designed and built his own engraving machine which he uses to make printed circuit boards (for through- His electronic designs are generally intended to improve on the performance of commercial products, ranging from alarm systems to optical communication and automotive instrumentation. But also odd bits and pieces of household gadgetry and mechanical curiosities. Peter can be contacted by email |

|

Paul Perkins |

Paul’s principal interest lies in 3- He has been involved in Reprap from early days, and is practised at building, repairing and using 3- Stemming from his use of stepper motors in 3- Paul can be contacted by email |

|

Brendan Phelan |

Brendan's principal interest is in tooling for his home workshop, having made for his own use a Stent tool and cutter grinder, a dividing head, some vices, and lathe tooling for a Myford ML7. Using these and other tools in his comprehensive modelling workshop he has a continuing interest in the design and construction of jigs and tools for particular purposes. He has a professional background in the electronic control systems of commercial jet engines. His experience in the manufacture of printed circuit boards using chemical process, professionally and for home use, is still relevant, although some are using engraving for prototype construction. He has enjoyed building and operating model aircraft, and racing model yachts, power boats and cars, and when he has time he is working on a Seal 4- He has been using 3D- Brendan can be contacted by email |

|

Julian Wood |

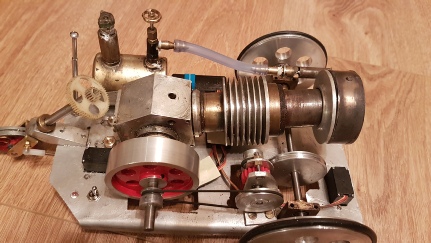

I suppose I was born a typical engineer. From very early days I always wanted to build things that really worked. This interest centred on models and electrical devices which later provided me with a career. These included radio receivers, solar and wind power and engines of all types. This latter meant I needed a machine shop, having learnt machining during early training, and led eventually to steam engines. For these, boilers were a necessary and demanding problem which was not solved to my satisfaction until I came across Stirling engines. These provided an instant addiction: the fascination of thermodynamic cycles, production of efficient and silent energy and the seemingly infinite range of designs and arrangements. So I set about getting to grips with the various proportions and materials involved. Since then I have made several hundred Stirling engines, both stationary and automotive, but mainly toy- Meanwhile I am working on drive systems for model- Julian can be contacted by email |